New Equipment

Farm King - CONVENTIONAL AUGER MOVER

-

ID # 28041577

- Back ID:28041577

- Get Directions

Farm King - CONVENTIONAL AUGER MOVER:

Farm King has a redesigned mover system that compliments the 8” & 10” diameter x 41’, 51’ & 61’ length CX2 augers. Newly engineered Motor Drive Mechanism has a bigger sprocket and ring gear on the wheel assembly. The fuel tank with gauge has been relocated for easier access for filling. The control console has better ergonomic hand bars as well the added features of working light & electric clutch toggle switches. Clear visual instruction decal is provided for the operator on the surface of the console.

The console is placed at the ideal height for operator safety and control. The pivot wheel is able to lock into place which provides the operator with easier steering once the auger is lined up to the bin. The transport safety chain has been modified for ease of hookup.

Features:

- Power steering

- Central control location

- Mover mounts to undercarriage only

- Rear wheel lifts for eay transport

MOVER CONTROLS -

The auger mover controls are located near the engine controls, allowing for one location control. The belt guarding doubles as the engine leveling device, which keeps the belts at the same tension in any auger position.

CASTER WHEEL -

The unique caster wheel design and independently powered drive wheels allow an extremely short turn radius. The intake end scissor lift allows a wide range of vertical motion and tucks up under the auger tube for easy transport.

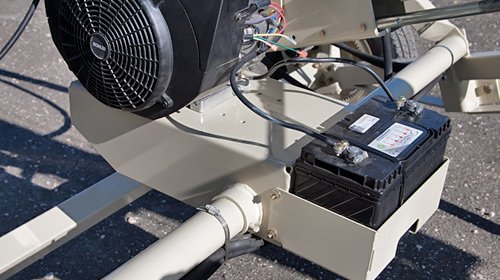

ENGINE MOUNT -

The engine mount plate has no moving parts for ease of set up. The engine drive sheave is now standard equipment. The drive belts are engaged via a newly designed lever accessible from the auger and engine control location.

| Specifications | |

|---|---|

| Pivot wheel tire size | ~ 19" diameter |

| Hydraulic cylinder size | 2" diameter |

| Hydraulic tank volume | 6 gal |

| Weight | 1,723 lb |

MOVER CONTROLS

|

CASTER WHEEL

|

ENGINGE MOUNT

|

|