Farm King

Farm King - BACKSAVER AUGER

-

ID # 28041572

- Back ID:28041572

- Book a Demo

- Get Directions Get Directions

Farm King - BACKSAVER AUGER Models 10", 13" and 16":

With the unique SCISSOR LIFT undercarriage, operational speed and lift of the auger has never been smoother or easier. The scissor lift design is available on ALL BackSaver augers.

With the Scissor Lift design, farmers are able to get closer to grain bins and are able to lock the auger lift hydraulics when in the desired location by using the safety ball valve lever. By providing steel cables and solid bridging on our BackSaver augers, Farm King has ensured stability and peace-of-mind during operation. The steel bridging of the 13” x 114’ auger provides exceptional stability and smooth lift under very windy conditions. Transporting your BackSaver auger made easy with a maximum transport height of 15'.

Models range in lengths of 50’ to 114’ with your choice of 10”, 13” and 16” diameter tubing. The recommended horsepower for peak operation ranges from 40 Hp to 175 Hp depending on auger diameter and length that is required for maximizing performance on your farm or grain handling operation.

Models 10" and 13":

FARM KING BACKSAVER AUGERS ARE PRACTICAL, ECONOMICAL AND DEPENDABLE.

That dependability has been a benchmark of Farm King BackSaver Augers for many decades. Auger tubing sizes are available in 10" or 13" diameters and lengths ranging from 50 to 114 feet. The 43-1/2" x 60" intake hopper invites large quantities of grain to be quickly moved up the auger and into the bin.

16" Model:

THE 16" FARM KING GRAIN AUGERS ARE DESIGNED BY THE PEOPLE WHO KNOW AND UNDERSTAND YOUR GRAIN HANDLING NEEDS.

The large 16" tubing by up to 104' length allow the operator to move large quantities of grain in short periods of time. Equipped with a 3" lighting shaft, the Farm King auger handles even the dampest crops with ease.

Features:

SELF-LEVELING -

The self-leveling hopper on the swing-away auger will remain level regardless of auger height. The unique design allows the intake hopper to be loaded on uneven terrain. Increased flexibility relieves the hopper of unnecessary down pressure on all hopper parts.

HYDRAULIC CYLINDERS -

Powered by a heavy-duty hydraulic cylinder (two on model 16104, shown), the unique scissor lift undercarriage is capable of holding the auger at a 44° angle when fully extended. With the cylinders completely compressed, the auger angle changes to 5° in transport mode.

HYDRAULIC CONTROLS -

Using the auger-mounted hydraulic controls, the swing away auger can be lifted into position for transport and the hopper can be moved back and forth. This system removes most of the physical labor that was once required during grain handling.

ADJUSTABLE LIGHT -

A lighting kit, available on 16" models, provides light where it is needed most when unloading after hours. One light, located on the swing-away auger, provides light to the hopper and truck unloading area. Another light on the end of the auger tube directs light to the auger spout. The high quality, flexible spout is standard.

UNDERCARRIAGE -

The scissor lift undercarriage, exclusive to Farm King BackSaver Augers, requires less hydraulic pressure to raise and lower the auger. The wide undercarriage is stable and solid while still meeting transport requirements. Once positioned, a shut-off valve on the underside of the auger tube limits the circulation of the hydraulics so the auger will maintain its height.

DUAL SPOOL VALVE -

The optional two spool valve allows for hydraulic operation of the intake hopper winch and the hopper mover while only using two remote valves. The hydraulic controls eliminate the need to operate the winch and intake hopper by hand.

Options:

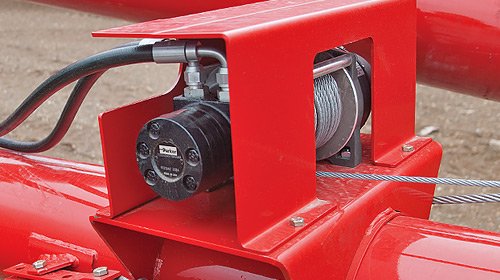

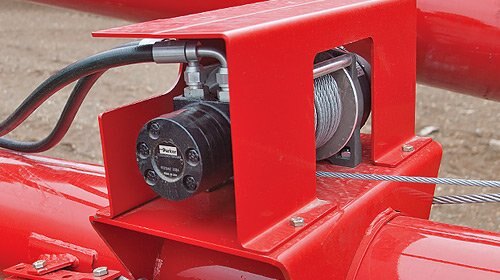

HYDRAULIC WINCH -

An hydraulic winch easily lifts the hopper into place for transport. The lever and hydraulic valve are mounted to the main auger tube for easy access. Standard on model 16104 and optional on 10" and 13" BackSaver models.

HYDRAULIC DRIVE WHEELS -

Each 16104 Farm King auger comes standard with a hydraulically controlled intake hopper. By simply moving the hydraulic lever, the intake hopper can be moved into precise position under hopper bottom and end dump trucks. Optional on 10" and 13" models.

HYDRAULIC HOPPER MOVER -

The standard hydraulic hopper mover adds a powerful hydraulic motor to each of the inside wheels on the swing away hopper so the hopper can be positioned easily and with minimal effort. The control lever for the mover is mounted on the intake auger tube for easy access. Optional on 10" and 13" models.

SELF-LEVELING

|

HYDRAULIC CYLINDERS

|

HYDRAULIC CONTROLS

|

ADJUSTABLE LIGHT

|

UNDERCARRIAGE

|

DUAL SPOOL VALVE

|

HYDRAULIC WINCH

|

HYDRAULIC DRIVE WHEELS

|

HYDRAULIC HOPPER MOVER

|

|

|

Request More Info

Request More Info

Quick Links

Hours

Monday - Friday

7:00AM - 5:00PM

Saturday

8:00AM - NOON

Sunday

Closed